Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 22, 2024 Visit:337 Source:ROLL FORMING MACHINES LTD

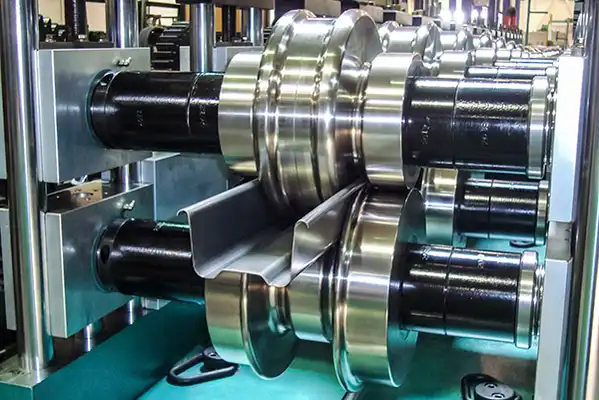

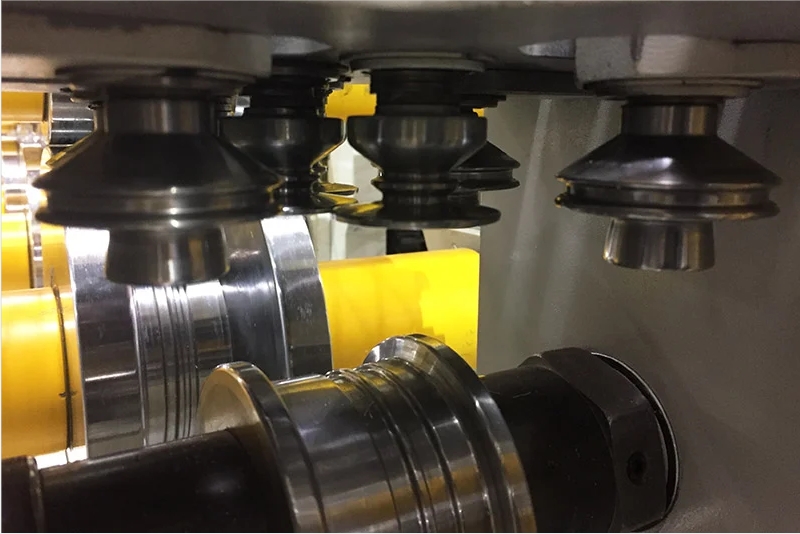

In the realm of modern manufacturing, the evolution of roll forming machine technology has been a cornerstone in driving efficiency and precision. This technology, which involves the continuous bending of flat metal sheets into desired shapes through a series of precision-engineered rolls, has undergone significant advancements in recent years. These innovations have not only refined traditional processes but also unlocked new potentials for enhancing production workflows and optimizing resource utilization.

One of the key advancements in roll forming machine technology lies in the enhanced precision and accuracy of the machines. With the integration of advanced sensors and control systems, modern roll forming machines can now achieve tolerances that were previously unattainable. This heightened precision allows for the production of components with complex geometries and tight tolerances, thereby reducing the need for secondary operations such as trimming and grinding. Consequently, manufacturers can now achieve higher levels of quality and consistency in their products, leading to reduced waste and increased productivity.

Moreover, the automation of roll forming machines has taken a leap forward, enabling seamless integration with other manufacturing processes. Through the use of advanced robotics and automation systems, roll forming machines can now operate continuously, with minimal human intervention. This level of automation not only streamlines production lines but also enhances safety by reducing the risk of human error and eliminating the need for manual handling of heavy materials. Furthermore, automated roll forming machines can be programmed to switch between different product configurations, enabling manufacturers to quickly adapt to changing market demands and reduce setup times.

The advent of intelligent diagnostics and predictive maintenance has also been a game-changer in roll forming machine technology. By leveraging IoT (Internet of Things) and AI (Artificial Intelligence), manufacturers can now monitor the performance of their roll forming machines in real-time, detecting potential issues before they escalate into costly failures. Predictive maintenance algorithms analyze historical data and operational parameters to forecast when maintenance is required, enabling proactive action and minimizing downtime. This proactive approach to maintenance not only ensures the reliability and longevity of the machines but also maximizes their uptime, thereby enhancing overall manufacturing efficiency.

Another significant advancement in roll forming machine technology is the integration of cutting-edge materials and processing techniques. As materials science progresses, roll forming machines are now capable of working with a wider range of metals, including high-strength alloys and advanced composites. These materials offer enhanced performance characteristics such as increased strength, corrosion resistance, and lighter weight, which are crucial for applications in industries such as aerospace, automotive, and construction. The ability to process these advanced materials with precision and efficiency is a testament to the versatility and adaptability of modern roll forming machines.

In conclusion, the advancements in roll forming machine technology have had a profound impact on manufacturing efficiency. From enhanced precision and accuracy to increased automation and intelligent diagnostics, these innovations have enabled manufacturers to optimize their production processes, reduce waste, and increase productivity. As technology continues to evolve, the potential for further improvements in roll forming machine technology remains vast, promising even greater efficiencies and capabilities in the future. The manufacturing industry stands to benefit significantly from these ongoing advancements, as they pave the way for more streamlined, efficient, and cost-effective production workflows.