Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 22, 2024 Visit:50 Source:ROLL FORMING MACHINES LTD

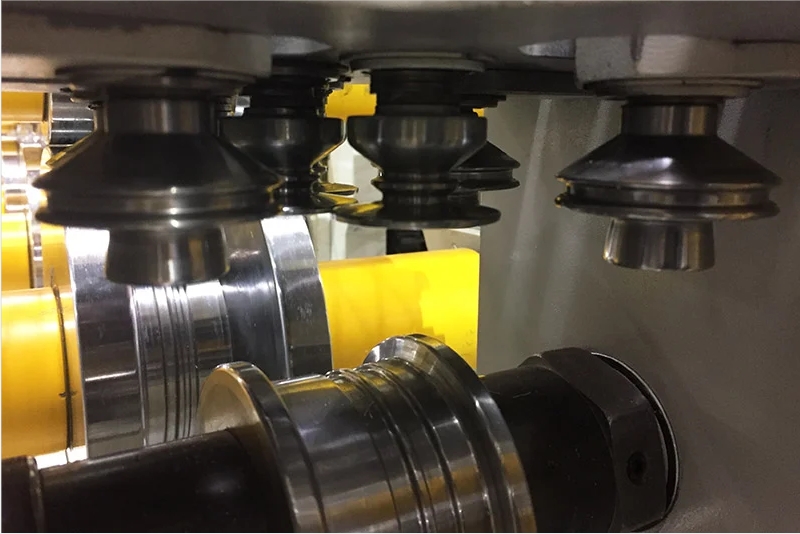

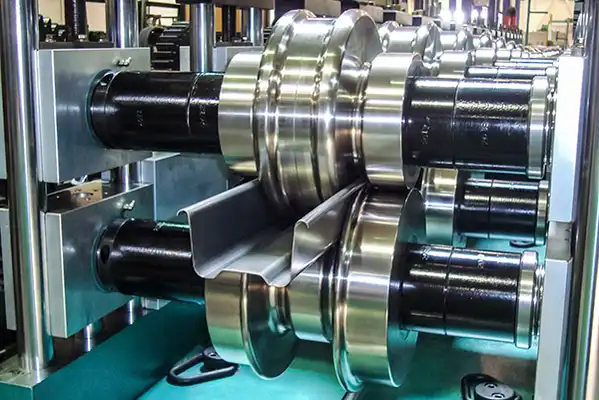

The field of manufacturing is continually evolving, driven by the need for efficiency, precision, and versatility. Among the various tools and machines that have played pivotal roles in this evolution, roll forming machines stand out due to their adaptability and widespread applicability across multiple industries. From automotive to construction, and from aerospace to electronics, the applications of roll forming machines have expanded significantly, contributing to the growth and advancement of numerous sectors.

In the automotive industry, roll forming machines are essential for the production of complex structural components. From roof racks and door frames to bumper beams and exhaust systems, roll forming enables manufacturers to produce these components with high precision and consistency. The ability to shape metals into intricate shapes and maintain tight tolerances is crucial for ensuring the safety, performance, and aesthetics of modern vehicles.

The construction industry has also benefited greatly from the versatility of roll forming machines. Steel beams, roof trusses, and other structural elements can be efficiently produced using roll forming technology. This method allows for the creation of strong, lightweight, and cost-effective building materials that meet or exceed industry standards. As the demand for sustainable and energy-efficient buildings grows, roll forming machines are increasingly being used to produce innovative materials that meet these requirements.

The aerospace industry is another sector where roll forming machines have made a significant impact. Components such as aircraft fuselage sections, wing spars, and landing gear components require a high degree of precision and strength. Roll forming machines are capable of producing these components with the necessary accuracy and consistency, ensuring the safety and reliability of aerospace vehicles.

The electronics industry has also embraced roll forming technology for the production of components such as enclosures, brackets, and housings. The ability to create intricate shapes and tight tolerances makes roll forming an ideal choice for producing high-quality, durable components that can withstand the rigors of electronic applications.

In addition to these traditional industries, roll forming machines are also finding new applications in emerging sectors. For example, in the renewable energy industry, roll forming machines are used to produce components for solar panels, wind turbines, and other energy-harvesting systems. The precision and efficiency of roll forming make it an attractive option for producing components that must meet stringent performance and durability requirements.

Moreover, roll forming machines are being used in the medical industry for the production of surgical instruments, implants, and other medical devices. The ability to shape metals into precise shapes and maintain strict quality control standards is crucial for ensuring the safety and efficacy of these products.

As the manufacturing landscape continues to evolve, the applications of roll forming machines will likely expand further. The versatility and adaptability of these machines make them an invaluable tool for producing high-quality components across a wide range of industries. By leveraging the capabilities of roll forming machines, manufacturers can stay ahead of the competition, drive innovation, and deliver exceptional value to their customers.