Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 24, 2024 Visit:192 Source:ROLL FORMING MACHINES LTD

The manufacturing industry has witnessed significant transformations in recent years, driven by technological advancements, evolving customer demands, and global competition. Among the various tools and machines that have played a pivotal role in this evolution, roll forming machines stand out for their versatility and efficiency in shaping metal materials. As the demand for these machines grows, understanding the price trends in the roll forming machine market becomes crucial for both manufacturers and potential buyers.

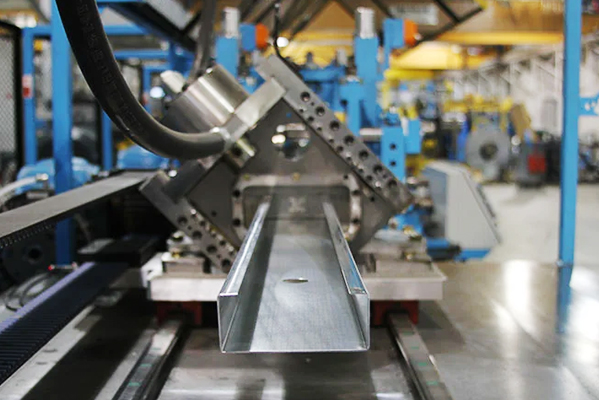

Roll forming machines are used extensively in the production of metal parts and components across various industries, including automotive, aerospace, construction, and electronics. These machines are capable of forming metal sheets into complex shapes and profiles through a series of rolling operations. The pricing of roll forming machines can vary significantly based on several factors, including machine specifications, brand, and regional market conditions.

One of the key factors influencing roll forming machine prices is the level of automation and technology incorporated into the machine. Highly automated roll forming machines, equipped with advanced control systems and robotics, tend to be more expensive than manually operated or semi-automated models. However, the increased productivity and precision offered by automated machines often justify the higher price tag for many manufacturers.

Machine specifications, such as the size of the rolls, the maximum thickness of the material that can be processed, and the speed of the machine, also play a significant role in determining the price. Larger and more powerful roll forming machines, capable of handling thicker materials and operating at higher speeds, generally cost more than smaller, less capable models.

Brand reputation and market positioning are another important aspect affecting roll forming machine prices. Well-known brands with a strong track record of delivering high-quality machines and excellent customer service tend to charge a premium for their products. However, this premium is often perceived as worthwhile by buyers who value reliability and support over price.

Regional market conditions also have an impact on roll forming machine prices. In regions with a high demand for metal forming equipment, such as North America and Europe, prices may be higher due to increased competition and limited supply. Conversely, in regions with lower demand or a more developed manufacturing base, prices may be more competitive.

Despite these variations, the overall trend in roll forming machine prices has been relatively stable over the past few years. With advancements in manufacturing technology and increased competition in the market, manufacturers have been able to offer more affordable pricing options while maintaining the quality and performance of their machines.

Moreover, the globalization of the manufacturing industry has led to an increase in the availability of roll forming machines from various countries. This has created a more competitive market environment, driving prices down and allowing buyers to choose from a wider range of options.

In conclusion, roll forming machine prices are influenced by a variety of factors, including machine specifications, brand, and regional market conditions. While there may be some variations in pricing, the overall trend has been relatively stable, with advancements in technology and increased competition driving more affordable options. As the manufacturing industry continues to evolve, understanding these price trends will be crucial for both manufacturers and buyers to make informed decisions and stay competitive in the market.