Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 23, 2024 Visit:179 Source:ROLL FORMING MACHINES LTD

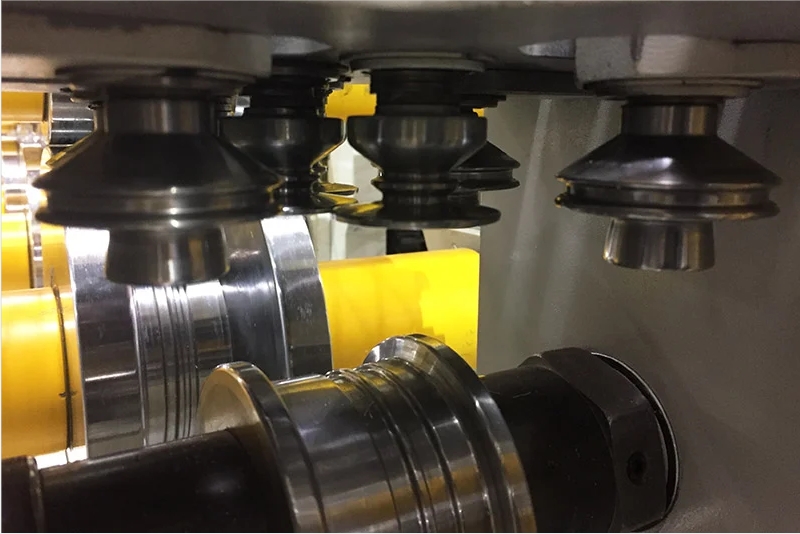

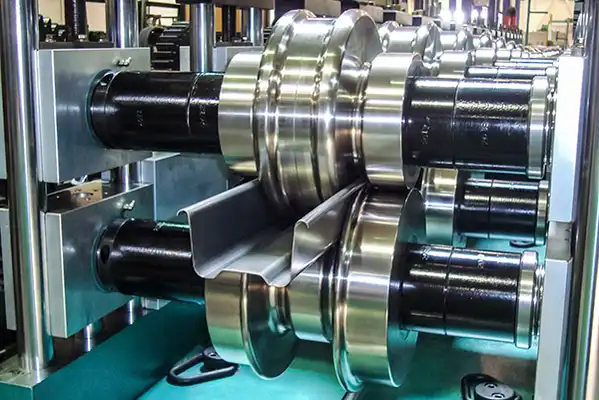

In the dynamic industrial landscape, the pricing of roll forming machines has consistently shown sensitivity to shifts in market demand. Roll forming machines, known for their ability to shape metal into various cross-sectional profiles through a series of rolling dies, are crucial in industries such as construction, automotive, and furniture manufacturing. This article explores how changes in market demand influence the pricing of these versatile machines.

Market demand for roll forming machines fluctuates based on several factors, including global economic trends, industrial production levels, and technological advancements. During periods of economic growth, industries tend to expand their production capacities, leading to an increased demand for machinery, including roll forming machines. Conversely, economic downturns often result in reduced industrial activities and, consequently, lower demand for such equipment.

Technological advancements also play a significant role in shaping market demand. As manufacturing processes evolve, industries seek more efficient and automated roll forming machines to improve productivity and reduce costs. This demand for advanced machinery can temporarily push up prices, especially if the supply chain has not yet adapted to produce these new models in sufficient quantities.

The automotive industry, a major consumer of roll forming machines, experiences cyclical demand patterns due to changes in consumer preferences and global sales trends. When new car models are launched or existing models undergo significant redesigns, manufacturers often require updated roll forming machines to produce components that meet new specifications. This temporary surge in demand can lead to price increases until the market adjusts.

Similarly, the construction industry's demand for roll forming machines is influenced by factors such as infrastructure projects, housing starts, and commercial building activity. In regions where construction activity is booming, the demand for roll forming machines to produce steel beams, roofing tiles, and other structural components increases. This heightened demand can result in higher prices and longer lead times for machine delivery.

On the supply side, manufacturers of roll forming machines face challenges in meeting fluctuating demand while maintaining profit margins. Production capacities are often limited by factors such as raw material availability, skilled labor, and manufacturing technology. When demand spikes, suppliers may struggle to keep up, leading to shortages and subsequent price increases. Conversely, during periods of low demand, suppliers may need to reduce production or offer discounts to clear inventory.

The global economic environment also impacts roll forming machine prices. Currency fluctuations, trade tariffs, and international shipping costs can all affect the final price consumers pay. For example, a strengthening domestic currency can make imported roll forming machines more affordable, while tariffs and shipping delays can increase costs.

In conclusion, the pricing of roll forming machines is a complex interplay between market demand, technological advancements, and global economic conditions. Manufacturers and buyers alike must stay attuned to these dynamics to make informed decisions. As the industrial landscape continues to evolve, so will the pricing trends for roll forming machines, reflecting the ever-changing needs and capabilities of the modern manufacturing industry.