Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 24, 2024 Visit:245 Source:ROLL FORMING MACHINES LTD

In the realm of manufacturing, the pursuit of excellence in product quality is paramount. Roll forming machine manufacturers have recognized this imperative and are increasingly focusing on precision engineering to ensure that their machines deliver unparalleled accuracy and reliability. This shift towards precision engineering is not just a trend; it is a strategic imperative driven by the evolving needs of the market and the demand for high-quality, custom-made products.

The Importance of Precision Engineering

Precision engineering involves the application of advanced techniques and technologies to achieve exact specifications and dimensions in manufacturing processes. In the context of roll forming machines, precision engineering ensures that the machines can produce parts and components with tight tolerances, consistent quality, and superior performance.

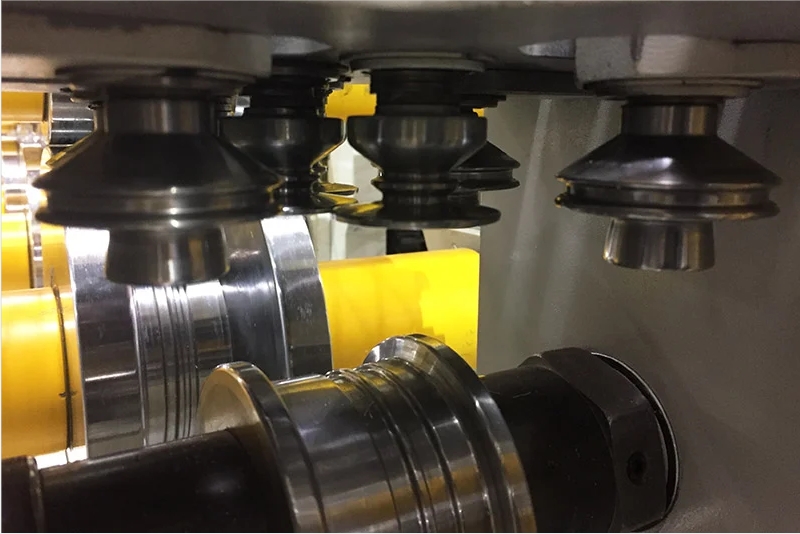

Roll forming machines are used to shape metal sheets into various profiles by passing them through a series of forming rolls. The accuracy of these rolls is crucial in determining the final shape and quality of the product. Any deviation in the roll's alignment or wear and tear can lead to inconsistencies in the formed profile, compromising the product's quality and functionality.

Advancements in Precision Engineering

To meet the demands of precision manufacturing, roll forming machine manufacturers have invested heavily in research and development. They have adopted advanced manufacturing techniques, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), to create highly accurate and reliable machines.

CAD and CAM systems enable manufacturers to design and simulate the roll forming process before it is implemented in real-world scenarios. This allows them to identify potential issues and optimize the machine's design to ensure that it meets the required specifications. Furthermore, the use of precision machining and grinding techniques ensures that the rolls are manufactured to exact dimensions, minimizing any deviations that could affect the final product.

The Role of Materials and Technologies

The materials used in the construction of roll forming machines also play a critical role in achieving precision. High-strength, wear-resistant materials, such as hardened steel and carbide, are now commonly used to make the rolls and other critical components. These materials are less susceptible to wear and tear, ensuring that the machines maintain their accuracy over extended periods of use.

Additionally, manufacturers are incorporating advanced sensing and control technologies into their machines. These technologies, such as laser sensors and closed-loop control systems, provide real-time feedback on the machine's performance and allow for immediate adjustments to maintain precision. By integrating these technologies, manufacturers can ensure that their machines consistently produce high-quality parts and components.

The Benefits of Precision Engineering

The focus on precision engineering in roll forming machine manufacturing has several benefits. Firstly, it enhances product quality by ensuring that parts and components are manufactured to exact specifications. This reduces the incidence of defects and inconsistencies, leading to higher customer satisfaction and reduced warranty costs.

Secondly, precision engineering improves production efficiency. Machines that are designed and manufactured with precision are less likely to experience downtime due to maintenance issues or part failures. This leads to increased uptime and throughput, allowing manufacturers to produce more products in less time.

Lastly, precision engineering enhances the versatility of roll forming machines. By incorporating advanced design and manufacturing techniques, manufacturers can create machines that can produce a wider range of profiles and materials. This versatility enables manufacturers to respond more quickly to market demands and capitalize on new opportunities.

Conclusion

In conclusion, roll forming machine manufacturers are increasingly focusing on precision engineering to enhance product quality. By adopting advanced design and manufacturing techniques, incorporating high-quality materials, and integrating advanced sensing and control technologies, these manufacturers are setting new standards for accuracy and reliability in the manufacturing industry. As the market continues to evolve, the pursuit of precision engineering will remain a critical factor in determining the success of roll forming machine manufacturers.