Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 22, 2024 Visit:167 Source:ROLL FORMING MACHINES LTD

The world of manufacturing is constantly evolving, driven by the relentless pursuit of efficiency, precision, and cost-effectiveness. Among the many technologies shaping this landscape, roll forming machines have emerged as a cornerstone in the production of complex metal shapes. Recent innovations in roll forming technology have not only enhanced the capabilities of these machines but have also significantly simplified the process of creating intricate metal forms, making it more accessible and efficient for manufacturers across various industries.

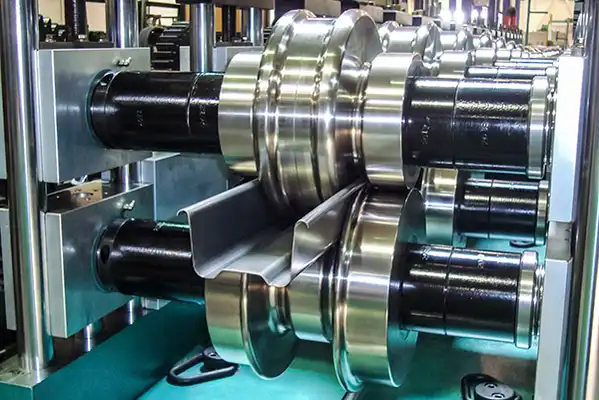

Traditional roll forming processes have been around for decades, primarily used to shape metals into continuous lengths of uniform cross-sections. However, with advancements in technology, roll forming machines have evolved to tackle more complex shaping tasks, offering manufacturers unparalleled flexibility and precision. These innovations have made it possible to produce components with tight tolerances, intricate geometries, and varied cross-sections, all while maintaining high production speeds and low material waste.

One of the most significant innovations in roll forming technology is the integration of advanced control systems. These systems, often powered by sophisticated software algorithms, enable manufacturers to fine-tune the roll forming process to achieve the desired shape with remarkable accuracy. By monitoring and adjusting the pressure, speed, and temperature during the forming process, these control systems ensure that each component meets the specified dimensions and tolerances, reducing the need for secondary operations such as trimming or grinding.

Moreover, the advent of multi-axis roll forming machines has further expanded the range of shapes and sizes that can be produced. These machines, equipped with additional forming rolls and sophisticated programming, can manipulate metal in multiple directions, allowing for the creation of complex three-dimensional shapes. This capability is particularly valuable in industries such as aerospace and automotive, where lightweight, high-strength components with intricate geometries are crucial.

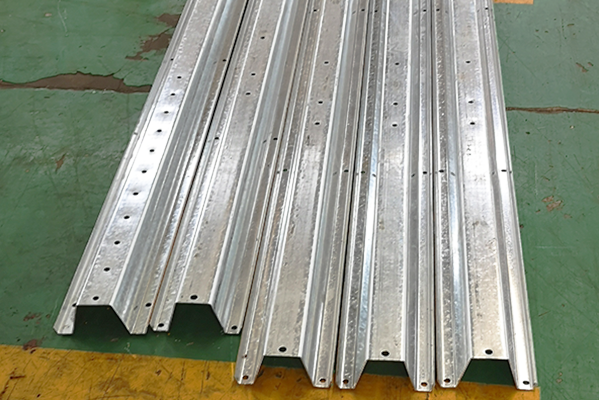

Another important innovation in roll forming technology is the use of high-strength materials. As manufacturers seek to reduce weight and improve performance, they are increasingly turning to materials like aluminum and advanced high-strength steels. Roll forming machines have adapted to these materials, incorporating specialized rolls and forming techniques that can handle their unique properties. This has enabled manufacturers to produce lighter, stronger components that meet the stringent requirements of modern applications.

In addition to these technological advancements, roll forming machines have also become more versatile and customizable. Manufacturers can now choose from a wide range of roll designs, materials, and configurations to suit their specific needs. This flexibility allows for the production of custom components tailored to unique applications, without the need for expensive tooling or extensive setup times.

The benefits of these innovations are evident across various industries. In the automotive sector, roll forming machines are used to produce components such as door frames, roof rails, and structural beams with intricate shapes and tight tolerances. In the construction industry, they are instrumental in the production of building components like roofing panels, wall systems, and structural framing. The aerospace industry relies on roll forming machines to create lightweight, high-strength components for aircraft and spacecraft, while the electronics sector utilizes them for the production of precision parts for electronic devices.

In conclusion, the innovations in roll forming technology have significantly simplified the process of creating complex metal shapes. By offering unparalleled precision, flexibility, and efficiency, these advancements have made roll forming machines an indispensable tool in the manufacturing landscape. As manufacturers continue to push the boundaries of what is possible, the ongoing evolution of roll forming technology will undoubtedly play a pivotal role in shaping the future of manufacturing.