Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 23, 2024 Visit:172 Source:ROLL FORMING MACHINES LTD

The roll forming machine industry has witnessed significant transformations in recent years, driven by technological advancements, market demands, and competitive pressures. Among these changes, pricing trends have emerged as a critical factor influencing the profitability and market position of manufacturers. This article delves into the cost and value dynamics shaping roll forming machine prices, offering insights into current trends and their implications for the industry.

Cost Considerations

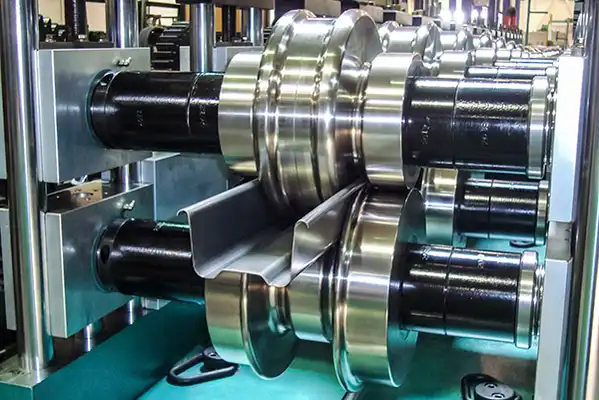

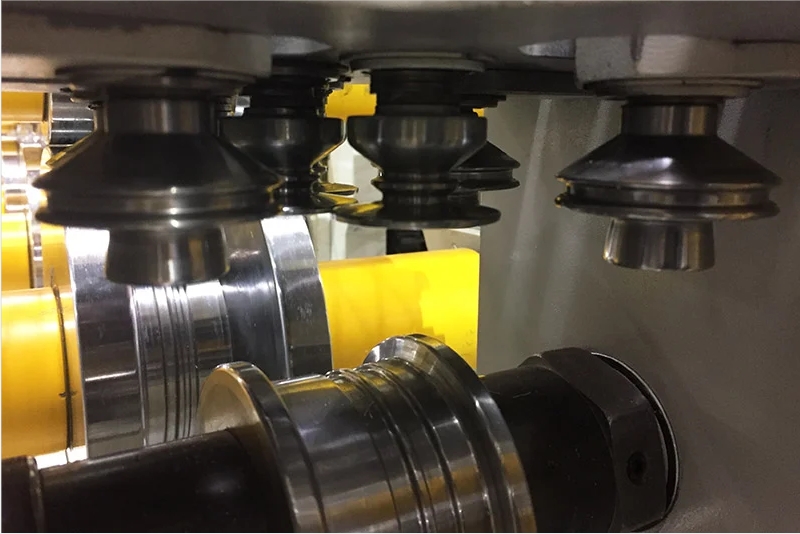

The cost structure of roll forming machines is multifaceted, encompassing raw materials, production processes, labor, overhead, and research and development (R&D). Raw materials, such as high-strength steel and precision machinery components, are a significant cost driver. Fluctuations in global commodity prices directly impact the cost of these materials, thereby influencing machine pricing.

Production processes also play a crucial role. Advanced manufacturing techniques, including automation and precision engineering, enhance the quality and efficiency of roll forming machines but come at a higher cost. Labor expenses, including skilled technicians and engineers, contribute to the overall production cost. Additionally, overhead costs, including rent, utilities, and administrative expenses, must be factored into the pricing equation.

R&D investments are essential for innovation and product development in the roll forming machine industry. These investments can lead to the creation of new technologies and features that enhance machine performance and user experience. However, they also add to the cost, necessitating a careful balance between innovation and affordability.

Value Proposition

The value proposition of roll forming machines extends beyond their manufacturing costs. Customers, including metalworking shops, automotive manufacturers, and construction firms, seek machines that offer precision, efficiency, durability, and versatility. Manufacturers must demonstrate how their machines deliver these benefits to justify their pricing.

Precision is a key value driver. Roll forming machines that can produce parts with tight tolerances and high accuracy are highly valued by customers. Efficiency gains, such as reduced setup times and increased production speeds, also contribute to the overall value. Durability ensures that machines perform reliably over extended periods, minimizing downtime and maintenance costs. Versatility, enabling machines to handle a wide range of materials and applications, broadens their appeal to a diverse customer base.

Pricing Trends

Current pricing trends in the roll forming machine industry reflect a delicate balance between cost and value. Manufacturers are increasingly adopting a value-based pricing approach, emphasizing the unique features and benefits of their machines to justify higher prices. This strategy is particularly effective in niche markets where customers are willing to pay for specialized solutions.

However, cost-conscious customers in highly competitive markets continue to drive down prices, forcing manufacturers to focus on cost optimization. This includes improving production processes, sourcing materials more efficiently, and leveraging economies of scale. Manufacturers are also exploring new business models, such as subscriptions and service contracts, to diversify their revenue streams and reduce price sensitivity.

Implications for Manufacturers

The evolving pricing trends in the roll forming machine industry present both challenges and opportunities for manufacturers. To remain competitive, manufacturers must continuously innovate and improve their machines to enhance their value proposition. This includes investing in R&D, adopting advanced manufacturing techniques, and collaborating with customers to understand their evolving needs.

At the same time, manufacturers must be mindful of cost pressures and seek opportunities to optimize their production processes. This includes negotiating better terms with suppliers, leveraging technology to improve efficiency, and exploring new revenue streams. By balancing cost and value effectively, manufacturers can navigate the pricing trends in the roll forming machine industry and achieve long-term success.

Conclusion

The pricing trends in the roll forming machine industry are shaped by a complex interplay of cost and value considerations. Manufacturers must navigate these trends by focusing on innovation, cost optimization, and customer collaboration. By doing so, they can create machines that deliver exceptional value to customers while maintaining profitable pricing strategies. As the industry continues to evolve, manufacturers must remain agile and adaptable to capitalize on emerging opportunities and overcome challenges.