Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 24, 2024 Visit:211 Source:ROLL FORMING MACHINES LTD

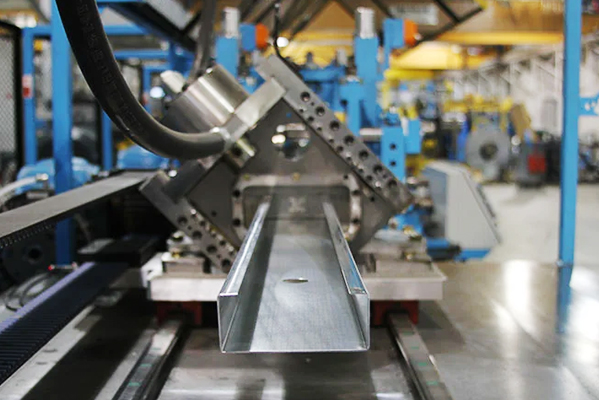

Roll forming machines are a cornerstone of modern manufacturing, particularly in industries that rely on the precise shaping of metal materials. From automotive parts to building components, these machines enable the production of a wide range of products with consistent quality and dimensional accuracy. However, the prices of roll forming machines can vary significantly, and their impact on production efficiency is a critical consideration for businesses making purchasing decisions.

Understanding Roll Forming Machine Prices

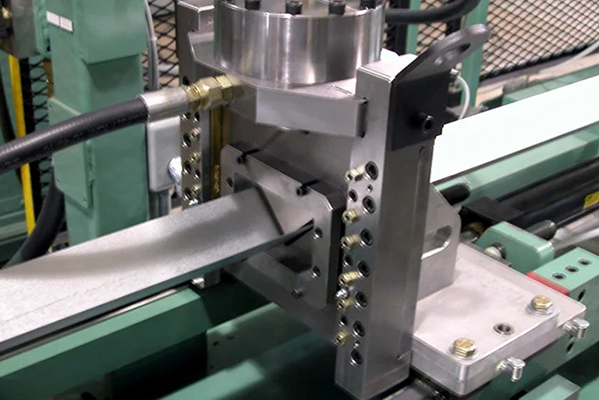

The pricing of roll forming machines is influenced by several factors, including the machine's size, complexity, and intended application. Machines designed for high-volume production or the processing of thick, heavy materials tend to be more expensive due to their robust construction and advanced features. Conversely, smaller, more specialized machines for low-volume or niche applications may have lower price points.

Customization also plays a role in pricing. Machines that require bespoke tooling, die sets, or control systems to meet specific production needs can cost more than standard models. Additionally, the brand and reputation of the manufacturer can affect pricing, as well as the level of after-sales support and warranty services offered.

Impact on Production Efficiency

The prices of roll forming machines can have a direct impact on production efficiency in several ways:

Initial Investment and Capital Allocation: Higher-priced machines often come with advanced features that enhance productivity, such as automated feeding, precision control systems, and rapid changeover capabilities. These features can significantly increase production rates and reduce downtime, leading to higher overall efficiency. However, the initial investment required for these machines can be substantial, necessitating careful capital allocation and potential financing arrangements.

Operational Costs and Maintenance: While high-end roll forming machines may have higher acquisition costs, they often offer lower operational costs due to their energy efficiency and reduced maintenance requirements. Conversely, less expensive machines may require more frequent repairs and replacements, leading to increased downtime and higher operational expenses.

Product Quality and Consistency: Machines with higher price tags tend to deliver better product quality and consistency, which is crucial for industries where precision and reliability are paramount. This can reduce waste and rework, further enhancing production efficiency.

Scalability and Flexibility: More expensive roll forming machines often offer greater scalability and flexibility, enabling businesses to adapt to changing production needs and market demands. This can be particularly important in dynamic industries where product diversity and rapid innovation are key drivers of success.

Balancing Cost and Efficiency

When considering the purchase of a roll forming machine, businesses must weigh the initial investment against the potential gains in production efficiency. This involves a thorough analysis of the machine's capabilities, the specific needs of the production process, and the long-term financial implications.

In some cases, investing in a higher-priced machine may be justified by the significant increases in productivity and quality it can deliver. In others, a more modest investment in a machine tailored to specific production requirements may be more cost-effective. The key is to find the right balance between cost and efficiency that aligns with the business's strategic goals and financial constraints.

Conclusion

In summary, the prices of roll forming machines have a direct impact on production efficiency, influencing factors such as initial investment, operational costs, product quality, and scalability. By carefully evaluating these considerations, businesses can make informed decisions that optimize their manufacturing processes and drive long-term success.