Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 24, 2024 Visit:179 Source:ROLL FORMING MACHINES LTD

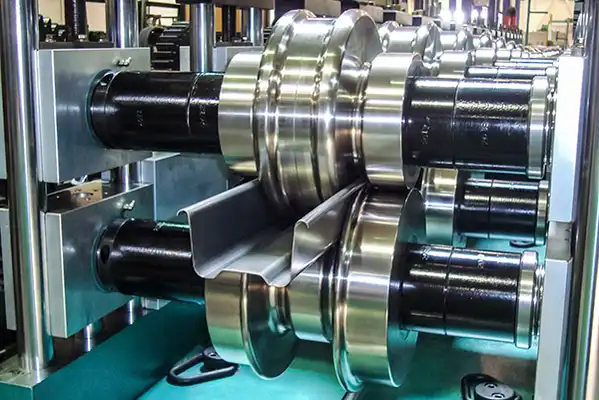

In the ever-evolving landscape of manufacturing, roll forming machines have become indispensable tools for shaping metal into a variety of complex and precise forms. As industries such as automotive, aerospace, and construction demand higher standards of quality and efficiency, manufacturers of roll forming machines have increasingly focused on precision and durability in their designs.

Precision is a paramount concern in roll forming machine developments. Modern roll forming machines are equipped with advanced control systems and sensors that enable them to achieve remarkable accuracy in shaping metal. These systems monitor and adjust the machine's operations in real-time, ensuring that each formed part meets the specified dimensions and tolerances. This level of precision is crucial for industries that require parts with tight tolerances and complex geometries, such as aerospace and automotive manufacturing.

To achieve such high levels of precision, manufacturers have incorporated advanced materials and manufacturing techniques into their roll forming machines. For instance, the use of high-strength alloys and precision machining processes ensures that the rolls and other critical components maintain their shape and performance over time. Additionally, the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems allows manufacturers to create custom roll forming solutions that precisely meet the unique needs of their customers.

Durability is another key focus area in roll forming machine developments. Manufacturers understand that their machines must withstand the rigors of continuous production and maintain their performance over extended periods. To achieve this, they have adopted robust design principles and materials that enhance the machine's structural integrity and wear resistance.

For example, many roll forming machines now feature heavy-duty frames and bearings that can support large loads and withstand high levels of stress. The rolls themselves are often made from hardened steel or other wear-resistant materials that maintain their sharpness and shape even after prolonged use. Furthermore, manufacturers have implemented lubrication systems and other maintenance practices that extend the lifespan of the machine's components and reduce the need for frequent repairs or replacements.

In addition to precision and durability, manufacturers of roll forming machines are also focusing on other aspects of machine performance, such as efficiency and flexibility. Advances in automation and robotics have enabled roll forming machines to operate with greater speed and consistency, reducing labor costs and improving overall productivity. At the same time, modular designs and quick-change roll systems allow manufacturers to easily adapt their machines to different production runs, enhancing their flexibility and responsiveness to market changes.

In conclusion, precision and durability are critical factors in the development of roll forming machines. Manufacturers are continuously innovating to improve the accuracy and reliability of their machines, meeting the evolving needs of industries that demand high-quality parts and efficient production processes. As technology advances, we can expect to see even greater improvements in the precision and durability of roll forming machines, driving further advancements in manufacturing and beyond.