Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 22, 2024 Visit:162 Source:ROLL FORMING MACHINES LTD

In the competitive world of manufacturing, staying ahead requires a commitment to continuous improvement and innovation. Leading manufacturers across various industries have recognized the value of investing in roll forming machine upgrades, recognizing that these enhancements can significantly boost productivity, improve product quality, and reduce operational costs.

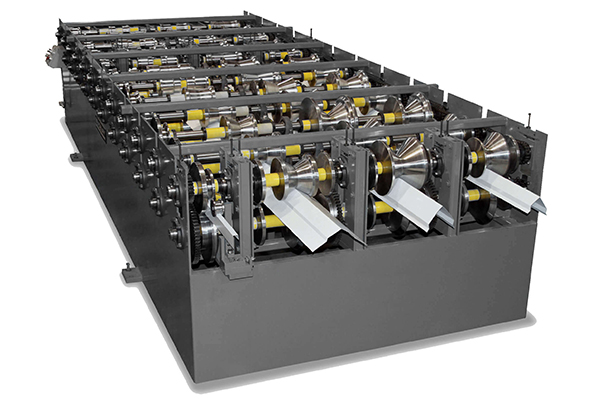

Roll forming machines have long been a staple in the production of metal components, enabling manufacturers to shape metals into continuous lengths of uniform or varying cross-sections. However, as technology advances and customer demands evolve, the capabilities of these machines must also adapt to meet new challenges. Leading manufacturers have responded to this need by investing in upgrades that enhance the precision, flexibility, and efficiency of their roll forming processes.

One of the primary motivations for upgrading roll forming machines is the pursuit of higher precision. As manufacturers strive to produce components with tighter tolerances and more intricate geometries, they require machines that can deliver unparalleled accuracy. Upgrades such as advanced control systems, high-precision sensors, and servo-driven rolls enable manufacturers to achieve this level of precision, ensuring that each component meets or exceeds specified dimensions and tolerances.

In addition to precision, flexibility is another key driver of roll forming machine upgrades. Leading manufacturers often produce a wide range of products, each with unique shapes and sizes. To meet these diverse needs, manufacturers are investing in roll forming machines that can be easily configured and retooled to produce different components. This flexibility allows manufacturers to quickly adapt to changes in customer demand, reducing lead times and improving responsiveness.

Efficiency is another critical factor driving roll forming machine upgrades. By incorporating advanced automation and robotics, manufacturers can streamline their production processes, reducing manual labor and minimizing downtime. These upgrades often include features such as automated feed systems, in-process inspection, and real-time monitoring, which enable manufacturers to maintain consistent production rates and minimize waste.

Moreover, leading manufacturers are investing in roll forming machine upgrades to improve product quality. By incorporating advanced materials and technologies, manufacturers can produce components with superior strength, durability, and surface finish. These enhancements can significantly improve the performance and lifespan of the final product, enhancing customer satisfaction and building brand reputation.

The benefits of investing in roll forming machine upgrades extend beyond the manufacturing floor. By improving productivity and reducing operational costs, manufacturers can allocate more resources to research and development, enabling them to stay ahead of the competition. Additionally, these upgrades can lead to significant energy savings, as more efficient machines consume less power and generate less waste heat.

In conclusion, leading manufacturers are recognizing the value of investing in roll forming machine upgrades. By enhancing precision, flexibility, efficiency, and product quality, these upgrades enable manufacturers to meet the evolving demands of the market, stay competitive, and drive continuous improvement. As technology continues to advance, manufacturers will likely see even more opportunities to leverage roll forming machine upgrades to optimize their production processes and deliver exceptional value to their customers.