Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 24, 2024 Visit:307 Source:ROLL FORMING MACHINES LTD

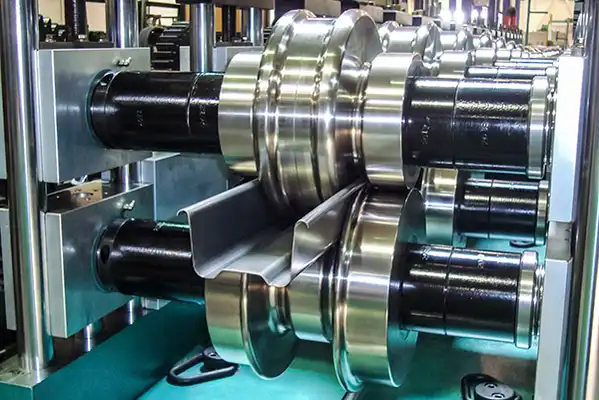

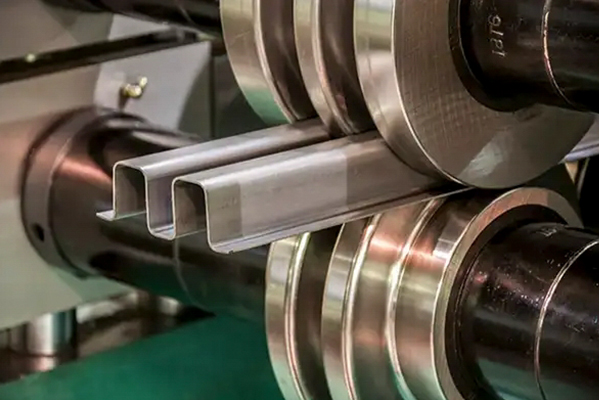

In the dynamic landscape of global manufacturing, roll forming machines play a pivotal role in shaping metal materials into a variety of products, from automotive components to architectural structures. As the industry evolves, pricing strategies for these machines have become increasingly nuanced, reflecting shifts in market demand, technological advancements, and competitive dynamics. This article explores the pricing strategies for roll forming machines in the global market in 2023.

Market Trends and Demand Dynamics

The pricing of roll forming machines is influenced by several market trends and demand dynamics. The global economic outlook, particularly in key manufacturing hubs such as China, Europe, and North America, plays a significant role. Economic growth and industrial expansion drive demand for these machines, while economic downturns can lead to a decrease in demand.

Moreover, technological advancements are shaping the pricing landscape. Innovations in automation, precision control, and material handling have led to the development of more sophisticated and efficient roll forming machines. These advanced machines often command higher prices due to their superior capabilities and the value they bring to manufacturing processes.

Competitive Pricing Strategies

In a highly competitive market, manufacturers of roll forming machines employ various pricing strategies to differentiate themselves and attract customers.

Value-Based Pricing: Manufacturers often adopt a value-based pricing strategy, focusing on the benefits and advantages their machines offer over competitors. This includes factors such as increased productivity, improved product quality, and reduced operational costs. By highlighting these value propositions, manufacturers can justify higher price points and attract customers who prioritize performance and reliability.

Cost-Plus Pricing: Another common strategy is cost-plus pricing, where manufacturers add a markup to their production costs to cover expenses and generate a profit. This strategy is often used in markets where competition is intense, and customers are price-sensitive. However, it requires careful cost management to ensure profitability.

Market-Based Pricing: Manufacturers may also adopt a market-based pricing strategy, adjusting their prices based on market conditions and competitor pricing. This can involve monitoring competitor offerings, understanding customer willingness to pay, and adjusting prices accordingly to maintain competitiveness.

Customization and Premium Pricing

Customization has become a key trend in the roll forming machine market. Manufacturers increasingly offer tailored solutions to meet specific customer needs, such as custom tooling, die sets, and control systems. These customized machines often come with a premium price tag due to the additional engineering and design work required.

However, the value proposition of customized machines is often significant. They can improve production efficiency, reduce waste, and enhance product quality, making them a worthwhile investment for many manufacturers.

Regional Pricing Variations

Pricing strategies for roll forming machines can also vary significantly by region. Factors such as local economic conditions, import tariffs, and transportation costs can affect pricing. Manufacturers often adjust their pricing strategies to account for these regional differences, ensuring that their machines remain competitive in each market.

Conclusion

In conclusion, the pricing strategies for roll forming machines in the global market in 2023 are shaped by a variety of factors, including market trends, technological advancements, competitive dynamics, and regional variations. Manufacturers must carefully consider these factors when setting prices to ensure that their machines remain competitive while delivering value to customers. By adopting flexible pricing strategies that align with market conditions and customer needs, manufacturers can drive growth and success in the global roll forming machine market.