Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 23, 2024 Visit:50 Source:ROLL FORMING MACHINES LTD

In the competitive manufacturing landscape, small to medium enterprises (SMEs) are constantly seeking innovative ways to enhance productivity and reduce costs. Roll forming machines play a crucial role in shaping metal sheets into desired profiles efficiently. These machines are particularly advantageous for SMEs as they offer versatility, precision, and scalability. When selecting cost-effective roll forming machine options, SMEs must consider various factors to ensure they make informed decisions that align with their operational needs and budget constraints.

Understanding Roll Forming Technology

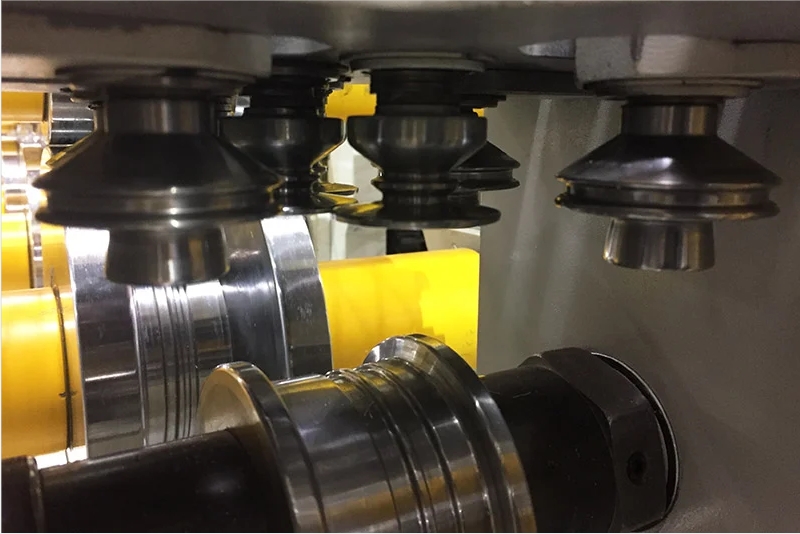

Roll forming is a continuous bending process where a flat metal strip is passed through a series of rollers that progressively shape it into the desired cross-sectional profile. This method is preferred over other forming techniques due to its ability to produce complex shapes with high accuracy and minimal material waste. Additionally, roll forming machines can operate at high speeds, making them ideal for large-scale production runs.

Factors to Consider

When exploring cost-effective roll forming machine options, SMEs should focus on the following factors:

Production Requirements: Assess your current and future production needs. Consider the types of profiles you need to produce, the material thickness, and the expected output volume. This will help narrow down the machine specifications that best suit your operations.

Machine Capabilities: Look for machines that offer flexibility in terms of roll set changes, which allow for the production of multiple profiles without significant downtime. Adjustable and interchangeable rolls can significantly enhance the versatility of the equipment.

Automation Levels: Depending on your budget and labor availability, consider the level of automation you require. Fully automated machines can increase productivity and reduce human error, but they tend to have a higher upfront cost. Semi-automatic or manually operated machines may be more cost-effective for SMEs with limited budgets.

Maintenance and Support: Evaluate the availability of maintenance services and technical support. Machines from established manufacturers are often supported by comprehensive warranty packages and dedicated customer service teams, which can minimize downtime and extend the equipment's lifespan.

Scalability: As your business grows, you may need to increase production capacity. Choose a machine that can be upgraded or scaled to meet future demands without requiring a complete replacement.

Cost-Effective Options

Here are some cost-effective roll forming machine options for SMEs:

Compact Roll Forming Machines: These machines are designed for small-scale production and are often more affordable than larger models. They are ideal for creating simple profiles and can be easily integrated into existing workflows.

Used and Refurbished Machines: Purchasing used or refurbished roll forming machines can be a cost-saving alternative. Ensure that the equipment has been thoroughly inspected and tested to verify its functionality and reliability.

Modular Roll Forming Systems: Modular systems allow for custom configurations based on specific production needs. They offer flexibility and can be expanded as required, making them a scalable and cost-effective option for SMEs.

Lease or Rental Options: If you have fluctuating production needs or are unsure about the long-term commitment, considering leasing or renting a roll forming machine can be a viable option. This allows you to access the necessary equipment without a significant upfront investment.

Conclusion

Investing in a cost-effective roll forming machine is a strategic decision for SMEs looking to enhance their manufacturing capabilities. By carefully evaluating production requirements, machine capabilities, automation levels, maintenance support, and scalability, SMEs can select a machine that meets their operational needs while optimizing costs. With the right roll forming machine, SMEs can improve productivity, reduce material waste, and stay competitive in the ever-evolving manufacturing industry.