Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 24, 2024 Visit:168 Source:ROLL FORMING MACHINES LTD

In the realm of manufacturing, the evolution of roll forming machine technology has been a pivotal force driving efficiency and precision. Over the years, significant advancements in this technology have not only transformed the metal forming process but also significantly enhanced the overall productivity and quality of manufactured products.

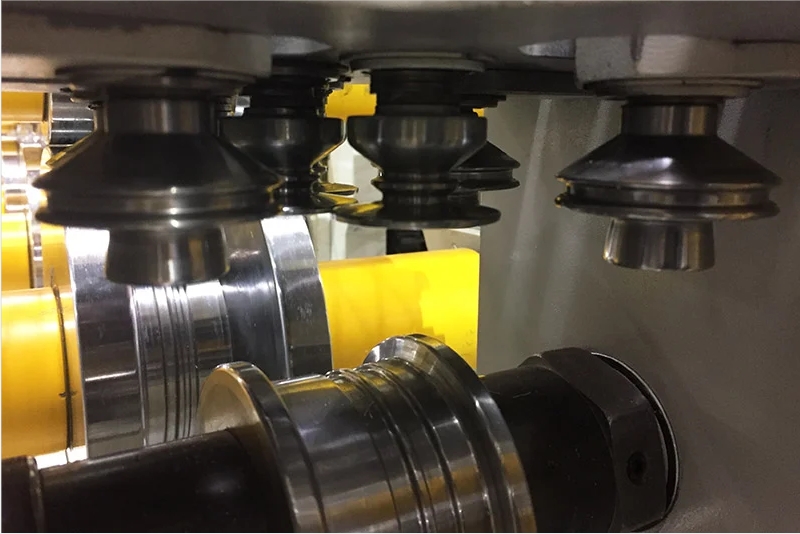

Roll forming machines are designed to shape metal sheets into desired profiles through a series of rolling dies. The process is highly efficient, allowing for continuous production of metal parts with consistent dimensions and shapes. The latest advancements in roll forming machine technology have further optimized this process, making it even more adaptable and reliable for a wide range of manufacturing applications.

One of the key advancements in roll forming machine technology is the integration of automation and robotics. These machines are now equipped with intelligent control systems that can automatically adjust parameters such as roll speed, feed rate, and forming pressure based on real-time data. This level of automation not only reduces the need for manual intervention but also ensures greater accuracy and consistency in the final product.

Furthermore, advancements in sensor technology have greatly improved the monitoring and control of roll forming processes. Sensors are now used to detect and correct deviations in material flow, temperature fluctuations, and other variables that can affect the quality of the final product. This real-time feedback loop allows manufacturers to make immediate adjustments, minimizing waste and maximizing productivity.

Material handling has also seen significant improvements with the latest roll forming machine technology. Machines are now designed with advanced feeding and conveying systems that can handle a variety of metal thicknesses and widths with ease. This flexibility allows manufacturers to switch between different materials and profiles quickly, reducing setup time and increasing overall efficiency.

In addition to these technological advancements, roll forming machines have become more modular and customizable. Manufacturers can now choose from a range of options and accessories to tailor the machine to their specific needs. This modularity not only enhances the versatility of the machine but also allows for easier maintenance and upgrades, ensuring that the machine remains up-to-date with the latest technological advancements.

The integration of digital technology has also played a crucial role in advancing roll forming machine technology. Manufacturers can now use computer-aided design (CAD) and computer-aided manufacturing (CAM) software to design and simulate the roll forming process before it begins. This predictive modeling helps to identify potential issues and optimize the process for maximum efficiency and quality.

Moreover, the use of data analytics and machine learning algorithms has enabled manufacturers to gain deeper insights into their roll forming processes. By analyzing data from sensors and other sources, manufacturers can identify trends, predict maintenance needs, and optimize machine settings for improved performance.

In conclusion, the advancements in roll forming machine technology have had a profound impact on manufacturing efficiency. By integrating automation, robotics, sensor technology, material handling improvements, modularity, and digital technology, manufacturers have been able to optimize their roll forming processes, reducing waste, increasing productivity, and improving product quality. As technology continues to evolve, the future of roll forming machines looks promising, with even greater efficiencies and capabilities on the horizon.